Commercial groundwork repair lives at the crossway of engineering, logistics, and also threat administration. It is actually certainly never just the unit price of a heap or the daily price of a rig. It is actually get access to, down time, the dirt document you prefer you possessed, the right staff for the equipment you decided on, and also the price of receiving stuck to the inappropriate unit for the subsurface you really have. When managers ask what helical piles or even resistance stacks expense, the truthful response is that both could be the least pricey choice or the most pricey blunder, depending on situations and objectives.

I have actually beinged in job trailers talking over redesigns after an exam pile delayed six feet short of torque, and I have actually viewed staffs go after capacity on push stacks via stuffing that didn't offer sufficient reaction to activate payload. Expenses open on those realities. The good news: with sensible assumptions and a very clear extent, you can anticipate a tight variety as well as decide on the correct device with confidence.

What disks price on commercial deep base repair

For commercial foundation repair, the 2 most common underpinning alternatives are helical piles as well as hydraulically steered protection piles, commonly gotten in touch with push piles. Micropiles belong in the very same chat when get access to, loads, or grounds press you outside the convenience zone of screw or even push systems. Tieback anchors, including helical tiebacks, entered play when sidewise loads or wall structure security matter as high as upright capacity.

The controlling variables are consistent across bodies. Use sets your guideline: moving a mini-excavator and also skid steer with a twist electric motor is actually really various from trucking in a practice gear and cement vegetation. Development costs establish work burn. Load matter and length range product costs. Checking and also exclusive inspection include time as well as charges. Eventually, site constraints, coming from clearance to vibration sensitivity, transform everything concerning ways and also methods.

On a traditional industrial retrofit, I anticipate total venture expenses to flock between 250 and 500 dollars every direct feet for helical piles and also in between 200 and also 450 bucks per straight foot for protection piles at moderate depths, supposing clean access as well as uncomplicated bunches. Micropiles usually jog greater, typically 400 to 900 dollars per foot, reflecting slower boring and grout, as well as tiebacks can easily land between 80 and also 180 dollars every feet relying on duration, strand or bar, as well as screening. Those are actually ballpark assortments, not quotes. Urban strategies, infected dirts, high-capacity brackets, or specialized corrosion security move the needle.

When helical piles pencil out

Commercial helical pile installation has gotten its position for foreseeable production and also marginal resonance. Helical piles are tightened into the soil along with a twist electric motor up until they reach an intended twist that correlates to ability. The unit beams where you possess:

- Controlled access, minimal space, or even the demand to work near active operations. You can install helical piles under a low ceiling, along a slab side, or even inside an occupant area along with little bit of disruption. Cohesive soils or even timeworn profile pages where twist associates effectively along with capability. This provides real-time feedback throughout setup that is invaluable for quality assurance and improvement management. Need for instant lots. No grout remedy, no hanging around period. The moment the stack strikes torque and also is secured off, the brace may take load. Lateral restriction demands. Helical anchors and also helical tieback anchor installation incorporates effortlessly along with deriving where wall structures require both upright assistance and sidewise stabilization.

The expense benefits appear in creation. The moment activated, a well-drilled staff can frequently install 10 to twenty helical piles every day in advantageous soils along with normal embedment spans in the 15 to 35 feet range. Component expenses depend upon shaft size as well as coil setup. A popular commercial mix is 2.875 in or even 3.5 inch round pole with 8-10-12 in triple helixes, or even 1.75 inch square bar in lighter-duty circumstances. Bigger shot bars, like 5.5 inch, handle higher compression tons as well as periodic needs but raise device cost.

On a latest retrofit of a retail pad structure, we set up 36 helical piles inside a working outlet over three nights. Access was via a rear roll-up along with 9 feet of clearance. The twist electric motor ran off a skid guide along with a spill frying pan, the flooring was actually shielded, and also component staging happened in the loading bay. Our company averaged 14 piles every night, 22 to 28 feets long, and attacked twist in tense filler over lean clay. All-in price per stack, consisting of engineering, enables, commercial helical pile installation effort, products, and also unique examination, landed near 11,500 dollars for the work, around 410 dollars per direct foot. The manager valued the routine as well as lack of resonance over sparing a couple of dollars on a press body that will have been actually riskier in the fill.

Where resistance piles bait value

Resistance piles, or push heaps, utilize the structure's weight as well as a gas port to push steel water pipes or steel pier sections to refusal. The capability is verified by the hoisting force achieved throughout installation. In the ideal ailments, commercial resistance pile installation may defeat helical overdo cost every feet and also provide great redundancy with end-bearing or skin friction.

The system conducts ideal when:

- The design has enough mass and tightness to give response without extreme hauling. Heavy concrete structures, thick slab-on-grade, and floor covering groundworks are ideal. Soils consist of thick sand, gravel, or even strong clay strata within practical intensity, allowing the pile to secure on end-bearing or set in motion abrasion efficiently. Vibration restrictions are strict, however twist is certainly not efficient because of cobbles or particles that will stall helices.

In my experience, manufacturing prices for protection heaps may match or go beyond helicals on available websites with good reaction. Crews frequently hit 8 to 16 stacks each day, and also the stack sectors are usually less expensive per feet. Brace options concern. For structural foundation repair on commercial websites, I avoid light-duty brackets designed for residential decks. Usage architectural braces rated for the genuine requirement with protection aspects aligned to the developer's criteria.

Where costs sneak: inadequate structure weight, improperly distributed reaction, or even tall airlift intendeds. If the piece cracks while you hoist, you get rid of opportunity on remedial shoring and also starch the budget plan. We once underpinned a tilt-up door line where the panels as well as roof covering design supplied loads of response, yet the surrounding workplace wing performed certainly not. Our company changed mid-run coming from press stacks to helical piles under the workplace side to stay clear of piece harm. That adjustment order added price, but lower than restoring a weakened slab.

Micropiles as the third path

Micropiles are small-diameter punched as well as grouted stacks with steel encouragement. They are the safety valve when helicals torque out early in dense grounds or when resistance stacks may not propel as a result of limited reaction. Micropile installation is actually slower, needs a rotary tool gear and grout vegetation, and also needs to have treatment opportunity, however provides high capacity in essentially any type of geology. Micropiles likewise work in restricted sites making use of low-clearance rigs. On medical facilities, laboratories, and also historical properties, our team commonly count on micropiles to anchor in to experienced strata while taking care of resonances and negotiation risk.

Typical costs for industrial micropiles vary greater than helical or protection heaps due to boring, housing, steel, grout, as well as testing. Anticipate 400 to 900 dollars every feet with notable variability for casing dimension, rock sockets, and also encouragement. The payback is dependability where other systems will strain or even fail.

How geotechnical reality directs choice

You can steer proposal rates cognizant an inadequate extent. You may not drive soils to match your spreadsheet. Ability and also expense depend upon the subsurface profile and also just how it differs all over the impact. A singular mundane 80 feet away that shows thick sand at 18 feet does certainly not guarantee your pile will definitely find it at 18 feet. That is actually why preconstruction screening, backup preparation, as well as system rates for expansions matter.

Helical piles shed productivity in extremely thick sands, rocks, as well as cobble lenses, especially where coils struggle to progress without harm. Protection piles stumble in thick gentle clay-baseds or even deep natural coatings where the property's weight can certainly not deliver sufficient response to achieve the intended capacity prior to lift. Micropiles cut through each complications along with bored sockets, yet they carry higher price and a longer schedule.

If I possess late-stage swelling clays with variable moisture content under a stockroom, I lean toward helical piles with larger helices to boost bearing in the dependable perspective. If I have layered sand and gravel with groundwater at 6 feet, I often tend to favor protection piles or micropiles, depending upon response as well as quality control needs. If I have superficial base, all three units can easily conduct, but micropiles with brief stone sockets often succeed on certainty and also long-lasting performance.

Cost break downs you can in fact use

Owners want to know where the money goes. The observing breakdown shows typical commercial ventures at medium scale, mention twenty to 60 stacks. Actual numbers differ through market.

- Helical stacks: components may be 40 to 55 per-cent of price, effort twenty to 30 percent, tools 10 to 15 percent, screening and unique evaluation 5 to 10 percent, cost and also earnings the difference. Product cost relies heavily on shaft size and also helix stack. A 3.5 in around shaft with three-way coil could run 75 to 140 dollars every feet supplied, whereas a 5.5 inch shaft can easily increase that. Resistance stacks: heap portions are actually usually 50 to one hundred bucks per foot depending upon diameter and also wall surface fullness, brackets five hundred to 1,500 bucks each for commercial-grade units, and installment work can be lower if the establishment delivers really good reaction. Testing and lift surveillance add reasonable cost. Micropiles: pierce opportunity dominates. Case, bar, grout, and also centralizers add product heft. Use is bigger because of the gear and also grout plant. Special inspection and also tons screening prevail and also can add a recognizable line item.

If you require tieback anchors for lateral security, finances independently. Helical tiebacks are swift to install where soils permit, with materials around 40 to 90 dollars per feet as well as installation including identical amounts. Grouted tieback anchors with strands or pubs typically cost more every feet but provide higher capability in rough or even blended grounds. For commercial helical tieback anchor installation behind a retaining wall or cellar wall structure, creation can easily go to 6 to 12 supports every day with conventional grasps and also durations in the twenty to 40 foot range.

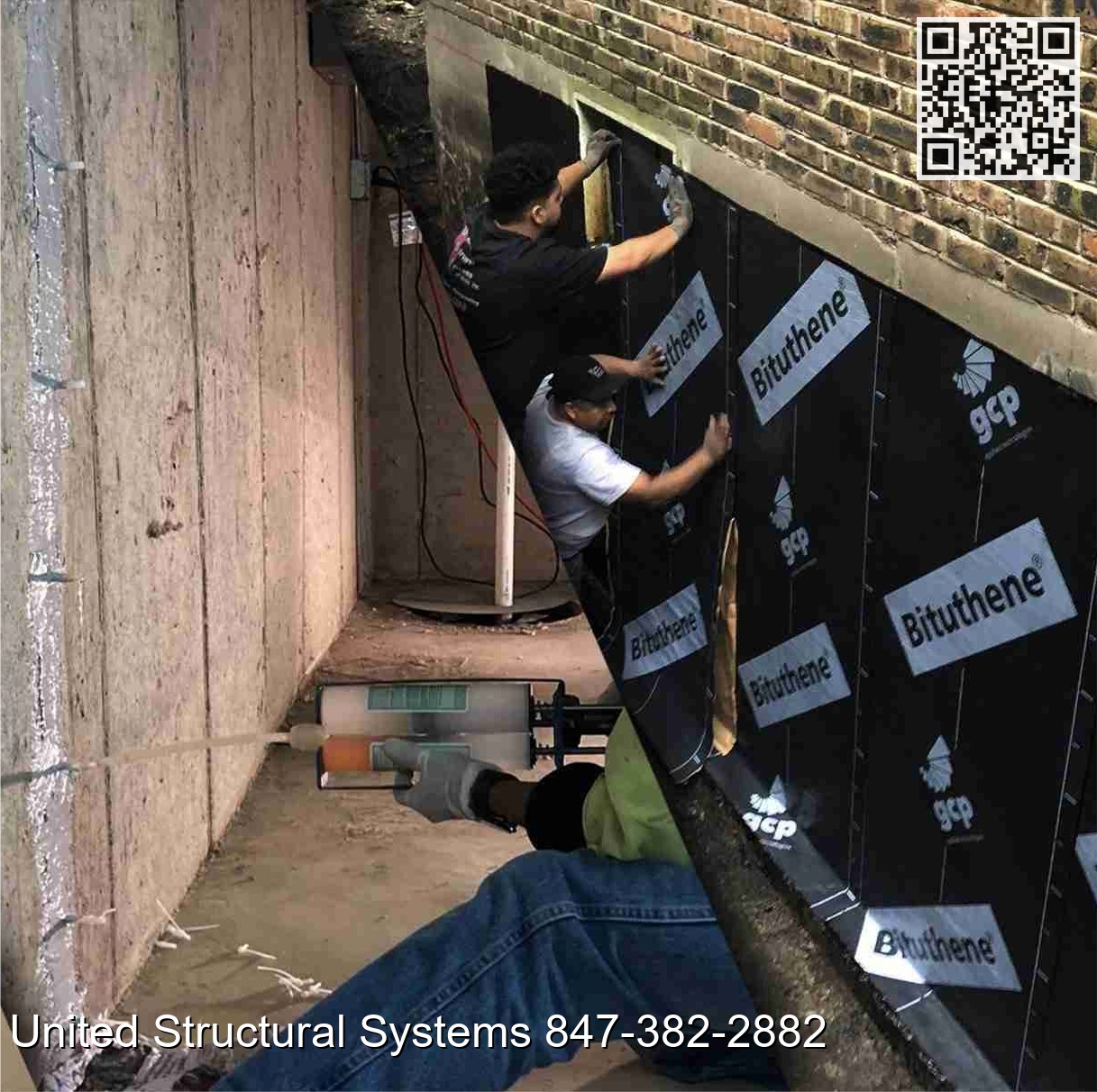

How installation get access to reshapes the estimate

Access defines equipment and staff size, which ripple in to your budget. A free outdoor line along a property may throw a mini-excavator along with a torque scalp and a skid guide. Inside an operating supermarket with 8 feet of clearance, you require an inconspicuous torque motor, well thought-out setting up, and also noise and also dirt controls. Every restraint injures production. Floor protection, evening job premiums, and trucking home windows incorporate soft costs that rarely show up in the first number you hear.

If the property can easily not put up with vibration or even resolution, your monitoring planning enters into the cost. Real-time altitude surveillance, tension gauges, and torque logging incorporate field and also records. They likewise spare rework. For structural foundation repair on sensitive internet sites, I budget for keeping track of early and also manage it as insurance.

Brackets, hats, and also the interface along with structure

Deep base repair service is actually just like the payload transfer. Underpinning brackets for helical piles as well as push piles vary extensively in capacity and also geometry. For business weights, pick brackets that line up with the engineer's factored payloads, the slab or even grade shaft thickness, as well as the reinforcement format. High-capacity brackets along with larger bearing places decrease nearby bearing stress and anxiety on concrete. Where possible, connect extra rebar and also cement to circulate load.

For foundation crack repair, carry out not perplex epoxy treatment or polyurethane shot with building fixity unless a developer requires it. Split repairs seal water as well as can connect fractured airplanes, but resolution as well as bearing breakdowns normally require deep-seated structure help. I often match split injection with underpinning, sequencing the deep foundation first to maintain motion, at that point securing cracks to control water.

Comparing life-cycle costs

Initial installation cost matters, however therefore carries out functionality over many years. Deterioration defense, bunch testing, as well as redundancy found life-cycle worth. Helical piles may consist of hot-dip galvanizing, sacrificial thickness, or cathodic security. Protection piles frequently utilize galvanized steel and could be sleeved in hostile grounds. Micropiles rely upon grout cover and also steel describing to fulfill deterioration standards. On coastal websites, industrial amenities, or where deicing salts are common, spend for defense up front. Retrofits later cost even more than the small devote now.

Serviceability also influences operations. Helical piles supply foreseeable settlement if mounted to torque requirements, however setup reports need to be actually complete, with torque versus intensity records, sector information, and lock-off bunches. Resistance stacks offer proof-of-capacity via jacking tension and also variation documents. Micropiles take advantage of bunch exams that specify approval criteria. Information streamlines potential resident enhancements and avoids unnecessary leveling when a brand new renter asks whether free throw line of rows they would like to relocate actually sits on underpinning.

Typical scenarios and what they cost

An office building with negotiation along one gulf line. Grounds show 8 feet of stuffing over rigid clay. Get access to by means of a back door. Twelve columns need base, 2 heaps every column, anticipated durations 25 to 30 feets. Helical piles are actually a strong prospect. All-in, I will budget plan 300,000 to 400,000 bucks, including commercial helical pile installation, engineering, allows, monitoring, and also patchback. If the clay-based is softer than assumed, incorporate an emergency for longer piles.

A tilt-up storehouse with section resolution and piece cracking. Dense sand below 12 feet along with perched water. Massive property offers response. Press piles may deliver, likely lower than helicals. Twenty heaps at 30 to 35 feet might land in between 250,000 and 350,000 dollars depending on brace and also testing requirements. Include allotment for piece sawcutting as well as rebar pegs where braces tuck under grade beams.

A historic movie theater with stooping cellar wall structures and also floor negotiation. Vibration limits are actually meticulous. Combined loaded with cobbles. Helical piles could strain, as well as protection piles take the chance of not enough reaction. Micropiles and grouted tieback anchors become the right devices. Anticipate 600,000 to 1,000,000 dollars for a bundled range of 30 to 40 helical pile foundations micropiles at 35 to 50 feet, twenty to 30 tieback anchors at 25 to 40 feets, split shot, and interior restoration, with a longer schedule.

Planning the job: inspection, testing, and also contingency

There is an appeal to move fast as well as permit manufacturing teams arrange it out in the field. That usually brings about transform purchases. I suggest at least two targeted borings or even CPT soundings per affected bay or wall operate. Where feasible, drive an examination helical pile or even a probing stack for push piles to confirm presumptions. Establish system costs for added span as well as a cost for body adjustment if industry shapes vary coming from the bid basis. For commercial foundation stabilization, that quality shields both manager as well as contractor.

Load testing deserves its own cost. An evidence exam on a helical or resistance pile early in creation can calibrate approval as well as stay clear of surprises. For micropiles, preproduction screening belongs to the typical process. Tieback anchors normally need evidence and also functionality examinations based upon the number put in. Build those tests into timetable and spending plan coming from time one.

Schedule facts and sychronisation along with operations

A warehouse that manages three shifts may not shut down for a full week of groundwork. Stage the work. Night puts in, minimal job home windows, as well as brief shoring all impact performance. Coordinate along with the customer's procedures group to deal with truck lanes, stockroom get access to, and noise. helical piles foundation applications On a grocery store job, our team installed helical piles inside along a refrigerated alley coming from 10 p.m. to 5 a.m. with audio curtains as well as a flooring protection program. Production came by 20 percent matched up to a free web site, but the retail store certainly never closed and also diminish stayed minimal.

Knowing when to incorporate systems

Hybrid remedies are common. Helical piles under the gently rich workplace airfoil, resistance heaps under the massive development flooring, and helical tieback anchors for a basement wall along with side pressure. Micropiles along a buried utility hallway where twist heads can certainly not run. The designer's job is to match device to subgrade and structure by region, not administer one solution anywhere. That subtlety boosts functionality as well as controls cost.

Contractor variety and also transparency

Ask for installment logs from prior tasks, certainly not merely endorsements. An experienced service provider is going to show twist charts for helical piles, hoisting records for protection piles along with attained capacity and also boost, grout take files for micropiles, and also load examination files for tieback anchors. They will definitely discuss their technique to unforeseen conditions as well as how they value extensions or redesigns. Commercial foundation repair rewards openness. Thus carry out cases insurers when traits go sideways.

A useful shortlist for selection makers

- Verify geotechnical circumstances along with targeted exploration and also, possibly, an exam stack just before full mobilization. Choose the system that straightens with ground actions, architectural reaction, access, timetable, and also risk resistance, certainly not the most affordable system price on paper. Demand quality assurance records: twist logs, hoisting files, grout takes, and bunch tests. Protect the user interface: point out commercial-grade braces, detail rebar and cement, and also strategy split repair work after stabilization. Budget for monitoring, corrosion protection, and documents. They pay for themselves over the lifestyle of the building.

Final word on costs as well as confidence

Helical stacks and also protection stacks both provide trusted, code-compliant base when utilized where they accommodate. Helicals frequently bait internal access, urgent load, as well as expected torque-to-capacity relationships. Protection stacks commonly bait price where framework body weight supplies tough response as well as dirts give great end-bearing or friction. Micropiles take the crown for complicated geography and also stringent vibration restrictions at a costs cost. Tieback anchors, featuring helical anchors, round out security when lateral loads get into the picture.

Put numbers to paper with reasonable assortments, acknowledge greats beyond, and get assurance where it matters. Commercial foundation repair is an industry game shaped by scientific research, certainly not a product. The right mix of examination, setup approach, and documentation is what switches an unsteady structure right into a steady property with a tidy report, certainly not simply a collection item that looked good in a proposal tab.